Home » Hospital & Durable Medical Equipment » How Shoulder Joint Models are Created » How Shoulder Joint Models are Created

How Shoulder Joint Models are Created

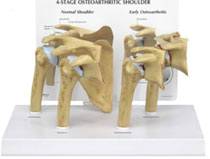

4-Stage Osteoarthritis Shoulder Model

Retail Price: $135.60

Your Price: $115.89

Unit: single

Unit: single

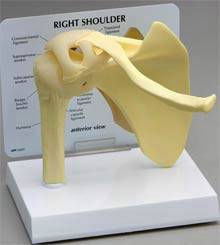

Life sized and incredibly accurate in even the smallest detail, shoulder joint models are a staple for patient consultations in most orthopedic offices. In addition emergency rooms, rehabilitation facilities and physical and occupational therapy programs also typically have these models on hand. They are ideal for discussing the movement and bone structure of the shoulder as well as how muscle, ligament, tendon and bone can be injured or damaged in trauma, accidents or disease.

Shoulder joint models, just like all other anatomical models, are very carefully designed. They are usually made by specialized artists that are trained in human anatomy as well as in working with resins and plastics. The first step in making human shoulder joint models is to start with an actual shoulder. This is a shoulder that has been donated for science and is considered to be free from any malformations or disease conditions. The shoulder is then placed in a resin or plastic mold and allowed to set. When the bones are removed an exact replica of the outside surface and shape of the shoulder is now available. This mold is then used to create a permanent mold, usually out of metal. Metal is the best material since it can tolerate the heating process without breaking down over time. In addition it is relatively easy to quickly cool.

Artists clean up the mold that is used to make the models to ensure that it is very lifelike in appearance. They also carefully examine each of the shoulder joint models removed from the mold to remove any debris or bits of resin. This is usually a minor time factor in producing the model since the molds are designed to be seamless and very effective in producing a uniform product.

In multi-bone types of models such as the shoulder, the bones may also be molded separately and assembled after cooling to create the final product. This is very common in the higher quality shoulder joint models and other joint models with movement possibility. Additional features such as tendons, blood vessels or major nerves are usually hand painted onto the model once it is fully cooled and free from any imperfections.

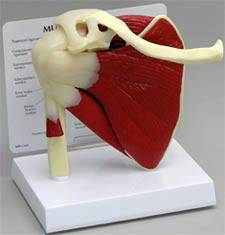

Some models, just as muscled shoulder models, combine more than one color of plastic or resin. With the process different colored parts of the model are created separately and then assembled after. This allows for bright color differences without any bleeding of the color. Additional features such as tendons are added separately to the muscle and bone component for easy distinction between the components.

Buying top quality shoulder joint models will make all the difference in your office, classroom or patient consultation room. The more accurate and realistic the model is the greater the understanding will be on the part of the patient or student. High quality models are also durable and long lasting. Additional features such as medical cards that sit behind the model on the base and identify the features of the model also are a great idea to promote understanding and clarity. This is true for both consultation and teaching since the visual information on the card will reinforce just what is being explained or discussed.

MSEC remains dedicated to providing the very best and the very latest in medical supplies and equipment. We never cease to be on the lookout for the latest innovation that will benefit both our many clients and the patients they dedicate their lives to caring for. If you have any difficulty finding your choices in our vast inventory, call our customer service at 1-877-706-4480 to speed up your order or to make a special request. We are always happy to help you.